High-Quality Flute End Mill for Precision Machining

By:Admin

Precision machining is a crucial aspect of modern manufacturing, as companies strive to produce high-quality parts and products with tight tolerances and intricate designs. One of the key tools that enable precision machining is the flute end mill. This cutting tool is essential for a wide range of applications, from milling and profiling to drilling and chamfering, making it an indispensable asset for machining operations.

A flute end mill is a type of milling cutter that is designed with multiple cutting edges on its cylindrical shape, allowing it to effectively remove material from a workpiece. These cutting edges, or flutes, come in various configurations, such as two, three, or four flutes, each offering different benefits for specific machining tasks. The flute end mill is typically made from high-speed steel, carbide, or other advanced materials to ensure durability and performance in demanding machining environments.

One company that has established itself as a leader in the production of high-quality flute end mills is [company name]. With a strong focus on innovation and precision engineering, [company name] has developed a comprehensive range of flute end mills that are trusted by machinists and manufacturers globally. Their cutting-edge manufacturing capabilities and rigorous quality control processes ensure that their end mills meet the highest standards for precision and reliability.

[Company name] provides a diverse selection of flute end mills to meet the varied needs of its customers. From standard end mills for general purpose machining to specialized tools for specific materials and applications, their product lineup covers a wide spectrum of machining requirements. Whether it's high-speed machining of aluminum or the precise milling of hardened steels, [company name] has the right flute end mill for the job.

One of the key advantages of [company name]'s flute end mills is their exceptional performance and long tool life. Through advanced engineering and cutting-edge technologies, their end mills deliver superior cutting speeds and feeds, resulting in increased productivity and reduced machining costs. Additionally, their tools are designed to withstand the demands of high-speed machining and heavy-duty cutting, making them ideal for modern manufacturing environments.

In addition to the standard offerings, [company name] also provides customized solutions for unique machining challenges. Their team of experienced engineers and technical experts work closely with customers to develop tailor-made flute end mills that address specific machining requirements, such as non-standard geometries or special coatings. This bespoke approach allows [company name] to support the evolving needs of the manufacturing industry and provide innovative solutions for complex machining tasks.

Furthermore, [company name] is committed to sustainability and environmental responsibility in its manufacturing processes. By utilizing advanced technologies and sustainable practices, they strive to minimize waste and energy consumption while maximizing the longevity and recyclability of their products. This eco-conscious approach aligns with the growing demand for sustainable manufacturing solutions and reinforces [company name]'s position as a responsible industry leader.

As the global manufacturing landscape continues to evolve, the role of precision machining in driving innovation and progress is more critical than ever. With its dedication to quality, innovation, and customer satisfaction, [company name] is well-positioned to meet the ever-increasing demands for high-performance flute end mills and support the advancement of modern manufacturing.

From standard to custom solutions, [company name] continues to set the standard for flute end mills, enabling machinists and manufacturers to achieve precision, efficiency, and success in their operations. With a relentless commitment to excellence, [company name] is poised to shape the future of precision machining and contribute to the ongoing advancement of the manufacturing industry.

In summary, the flute end mill is an indispensable tool for precision machining, and [company name] stands out as a leading provider of high-quality flute end mills that empower manufacturers to achieve their machining goals with confidence and efficiency. As manufacturing technology continues to advance, [company name] remains at the forefront of the industry, driving innovation and delivering cutting-edge solutions for the evolving needs of modern manufacturing.

Company News & Blog

The Ultimate Guide to CNC Router Mill: Everything You Need to Know

Milling and cutting have long been important processes in the manufacturing industry, and the development of computer numerical control (CNC) technology has revolutionized the way these processes are carried out. As technology continues to advance, CNC router mills have become increasingly popular due to their precision and efficiency. One company that has been at the forefront of this technology is {Company Name}.{Company Name} is a leading manufacturer of CNC router mills, specializing in the production of high-quality machines that are used in a wide variety of industries, including woodworking, metalworking, and plastic fabrication. With a strong focus on innovation and customer satisfaction, {Company Name} has earned a reputation for excellence in the field of CNC machinery.The {Company Name} CNC router mill is designed to provide exceptional accuracy and repeatability, making it an ideal choice for manufacturers who require high-precision machining. The machine's advanced control system allows for complex cutting and milling operations to be carried out with ease, while its robust construction ensures long-lasting durability.In addition to its technical capabilities, {Company Name} places a strong emphasis on user-friendly design, ensuring that operators can easily program and operate the machine, resulting in improved efficiency and productivity. The company also offers comprehensive training and support services to ensure that customers are able to make the most of their investment in a {Company Name} CNC router mill.One of the key advantages of the {Company Name} CNC router mill is its versatility. With a range of customizable options and accessories available, the machine can be tailored to suit the specific needs of each customer, whether they are working with wood, metal, plastic, or any other material.In recent years, {Company Name} has continued to innovate and evolve its product line, introducing new features and technologies that further enhance the performance of its CNC router mills. These advancements have been well-received by customers, who have praised the machines for their reliability, precision, and cost-effectiveness.The success of {Company Name} can also be attributed to its commitment to customer satisfaction. The company works closely with its clients to understand their unique requirements and challenges, and then develops tailored solutions that meet and exceed their expectations. This customer-centric approach has helped {Company Name} to build strong, long-lasting relationships with a wide range of manufacturers, from small businesses to large-scale industrial operations.Looking ahead, {Company Name} is poised to continue leading the way in the CNC router mill industry. With a focus on innovation, reliability, and customer satisfaction, the company is well-positioned to meet the evolving needs of manufacturers in a variety of industries.In conclusion, {Company Name} has established itself as a premier manufacturer of CNC router mills, offering high-quality machines that deliver exceptional performance and value. With a strong focus on innovation and customer satisfaction, the company is well-equipped to continue driving progress in the field of CNC technology. As manufacturing processes become increasingly advanced, {Company Name} is well-placed to remain at the forefront of this exciting industry.

Carbide Buttons and Tungsten Carbide Tool: Everything You Need to Know

China Carbide Buttons and Tungsten Carbide Tool, known for their high-quality carbide products, has recently announced a breakthrough in their research and development efforts. The company, established in 2007, specializes in the production of cemented carbide products such as carbide buttons, tungsten carbide tools, and carbide blanks. With a strong focus on innovation and customer satisfaction, China Carbide Buttons and Tungsten Carbide Tool has become a leading supplier in the industry.The company's dedication to continuous improvement and technological advancement has allowed them to stay ahead of the competition. Their state-of-the-art manufacturing facilities and stringent quality control measures ensure that their products meet the highest standards. With a team of experienced engineers and technicians, China Carbide Buttons and Tungsten Carbide Tool constantly pushes the boundaries of carbide technology, striving to develop cutting-edge solutions for their clients.Recently, the company's research and development team achieved a significant milestone in the development of a new carbide material. This breakthrough is expected to revolutionize the industry by offering enhanced performance and durability compared to existing products. The new carbide material is the result of extensive research and testing, utilizing advanced techniques and technologies to optimize its properties. This development underscores China Carbide Buttons and Tungsten Carbide Tool's relentless pursuit of excellence and their commitment to providing superior products to their customers.The innovative new carbide material is expected to have a wide range of applications across various industries, including mining, construction, and manufacturing. Its superior wear resistance, toughness, and thermal stability make it an ideal choice for demanding environments and high-stress applications. By offering this new material, China Carbide Buttons and Tungsten Carbide Tool aims to provide its customers with a competitive edge, enabling them to improve productivity and reduce operating costs.In addition to their cutting-edge products, China Carbide Buttons and Tungsten Carbide Tool takes pride in offering exceptional customer service and technical support. Their team of experts is dedicated to understanding each client's unique requirements and providing tailored solutions. Whether it's customizing carbide tools or providing expert advice on material selection, the company goes the extra mile to ensure customer satisfaction.Furthermore, China Carbide Buttons and Tungsten Carbide Tool is committed to sustainability and environmental responsibility. They adhere to strict environmental regulations and employ eco-friendly practices in their manufacturing processes. By prioritizing sustainability, the company aims to minimize its environmental footprint and contribute to a greener future.As China Carbide Buttons and Tungsten Carbide Tool continues to lead the way in the carbide industry, their latest breakthrough exemplifies their dedication to innovation and excellence. With their new carbide material, the company is poised to set new benchmarks for performance and reliability, cementing their position as a trusted partner for businesses around the world.In conclusion, China Carbide Buttons and Tungsten Carbide Tool's relentless pursuit of technological advancement and superior quality has placed them at the forefront of the carbide industry. Their innovative new carbide material represents a significant leap forward, offering enhanced performance and durability for a wide range of applications. With a strong focus on customer satisfaction and environmental responsibility, the company is well-positioned to meet the evolving needs of the market and drive industry progress.

High-Quality Flat End Mill for Sale: Find the Best Prices Online

End Mill Flat, a leading manufacturer of cutting tools, has recently introduced a new line of end mills to its already extensive product lineup. The company is known for its high-quality, precision-engineered tools that are used in a wide range of industries including aerospace, automotive, medical, and more. With this new offering, End Mill Flat is continuing its mission to provide cutting-edge solutions for its customers' machining needs.The new line of end mills features advanced design and cutting-edge technology that are aimed at improving efficiency and performance in machining operations. These end mills are designed to deliver superior results in terms of surface finish, precision, and tool life. With a focus on innovation and quality, End Mill Flat is committed to meeting the needs of its customers and staying at the forefront of the cutting tool industry."We are very excited to introduce our new line of end mills," said the company's spokesperson. "Our team of engineers and designers have worked tirelessly to develop these tools, and we believe that they will set a new standard for performance and reliability in the industry. We are confident that our customers will see the immediate benefits of using these end mills in their machining operations."End Mill Flat has built a strong reputation for delivering cutting tools that consistently outperform the competition. The company's commitment to research and development, as well as its investment in state-of-the-art manufacturing technology, has allowed it to stay ahead of the curve and meet the evolving needs of its customers. The introduction of the new line of end mills is yet another example of End Mill Flat's dedication to providing innovative solutions that drive success for its customers.In addition to its focus on product development, End Mill Flat is also known for its exceptional customer service and technical support. The company works closely with its customers to understand their specific machining challenges and provide tailored solutions that meet their unique requirements. This customer-centric approach has helped End Mill Flat build long-lasting relationships with its clients and solidify its position as a trusted partner in the industry.With the launch of the new line of end mills, End Mill Flat is poised to further enhance its standing as a leader in the cutting tool market. The company's commitment to quality, innovation, and customer satisfaction sets it apart from the competition and positions it for continued success in the years to come.As End Mill Flat continues to expand its product offering and reach new heights of excellence, its customers can rest assured that they are partnering with a company that is dedicated to their success. Whether it's aerospace, automotive, medical, or any other industry, End Mill Flat has the tools and expertise to help its customers achieve their machining goals.For more information about End Mill Flat and its new line of end mills, visit their website or contact the company directly. With a focus on performance, precision, and reliability, End Mill Flat is ready to meet the cutting tool needs of today and tomorrow.

Discover the Uses and Benefits of Metallic Tungsten

Metallic Tungsten is a cutting-edge material that has revolutionized various industries due to its exceptional properties and uses. The material has been at the forefront of technological advancements and has played a vital role in enhancing the performance and durability of various products. Its unique properties have made it an indispensable material in industries such as aerospace, automotive, electronics, and medical technology.Metallic Tungsten, also known as tungsten metal, is a dense, hard, and extremely strong material that exhibits exceptional heat resistance and high melting point. It is also highly resistant to corrosion, making it an ideal material for applications in harsh environments. These properties make metallic tungsten a preferred choice for a wide range of applications, such as high-temperature furnace components, electrical contacts, and radiation shielding.One of the leading producers of metallic tungsten is {}. The company has a strong reputation for delivering high-quality tungsten products to its global customer base. With a commitment to excellence and innovation, {} has established itself as a leader in the tungsten industry, providing customers with reliable and advanced solutions for their specific needs.The company's state-of-the-art manufacturing facilities and advanced technologies enable it to produce a wide range of tungsten products, including sheets, rods, wires, and custom parts. {}'s team of experienced engineers and metallurgists work closely with customers to develop tailored solutions that meet their exact specifications and requirements.{}'s metallic tungsten products are widely used in various industries, including aerospace, where the material is utilized in the manufacturing of high-performance components for aircraft and spacecraft. The exceptional strength and heat resistance of metallic tungsten make it an ideal material for critical aerospace applications, such as rocket nozzles, jet engine components, and structural materials.In the automotive industry, metallic tungsten is used for manufacturing high-performance engine components, such as valves, pistons, and bearings. The material's superior wear resistance and high-temperature performance make it an ideal choice for enhancing the durability and efficiency of automotive engines.The electronics industry also benefits from the unique properties of metallic tungsten, using it to produce advanced components for electronic devices, such as connectors, filaments, and heating elements. The material's high electrical conductivity and thermal stability make it an essential material for various electronic applications.In the medical technology sector, metallic tungsten is used for manufacturing radiation shielding components, such as syringe shields, collimators, and containers for radioactive isotopes. The material's ability to absorb and attenuate radiation makes it crucial for ensuring the safety of medical personnel and patients in diagnostic and therapeutic procedures.Moreover, {} is committed to sustainability and environmental responsibility in its operations. The company adheres to strict environmental standards and ensures that its manufacturing processes are efficient and eco-friendly. By implementing sustainable practices, {} aims to minimize its environmental impact and contribute to a greener and more sustainable future.With its dedication to excellence, innovation, and sustainability, {} continues to be a leading provider of metallic tungsten products, delivering advanced solutions to meet the evolving needs of various industries. Whether it's in aerospace, automotive, electronics, or medical technology, metallic tungsten plays a crucial role in enhancing the performance, reliability, and sustainability of products and technologies.As technological advancements and innovations continue to drive the demand for high-performance materials, metallic tungsten remains at the forefront of the industry, empowering manufacturers and engineers to push the boundaries of what's possible and achieve remarkable feats in various fields. With {}'s expertise and commitment to excellence, the future of metallic tungsten looks brighter than ever, paving the way for new possibilities and opportunities in the world of advanced materials and technology.

High-Quality Carbide Glass Cutter for Precision Cutting

Carbide Glass Cutter Leads the Way in Glass Cutting TechnologyIn today's modern world, the use of glass has become an integral part of various industries such as construction, automotive, and manufacturing. With the increasing demand for precision cutting of glass, the need for advanced glass cutting tools has become more crucial than ever. One company at the forefront of innovating glass cutting technology is [company name].[company name] has been a leading manufacturer of high-quality glass cutting tools for over two decades. The company has built a reputation for producing reliable and durable products that meet the needs of professionals in the glass industry. One of their flagship products, the Carbide Glass Cutter, has emerged as a game-changer in the field of glass cutting technology.The Carbide Glass Cutter is designed to provide precise and clean cuts on various types of glass, including single and double glazed windows, mirrors, and glass panels. Its innovative carbide wheel ensures that the glass is scored with accuracy and consistency, resulting in smooth and flawless cuts. The cutter's ergonomic design and non-slip grip make it easy to handle, reducing the risk of hand fatigue and ensuring maximum productivity during cutting tasks.One of the key features that set the Carbide Glass Cutter apart from traditional glass cutting tools is its superior durability. The cutter's carbide wheel is known for its high resistance to wear and tear, allowing it to maintain sharpness and effectiveness over prolonged use. This durability not only ensures long-term cost savings for users but also minimizes the need for frequent blade replacements, making it an economically viable choice for professionals.Moreover, the Carbide Glass Cutter is engineered to offer versatility, making it suitable for a wide range of applications. Whether it's cutting glass for construction projects, automotive repairs, or artistic endeavors, the cutter's precision and reliability make it an indispensable tool for professionals across different industries.In addition to its cutting-edge features, [company name] is dedicated to providing exceptional customer service and support. The company's commitment to quality is reflected in its rigorous quality control measures, which ensure that every Carbide Glass Cutter that leaves the production line meets the highest standards of performance and reliability. Furthermore, [company name] offers comprehensive training and technical assistance to users, empowering them to maximize the potential of their glass cutting tools.As the demand for high-quality glass cutting tools continues to rise, [company name] remains at the forefront of innovation, continuously striving to enhance its products' performance and functionality. With a strong focus on research and development, the company is dedicated to staying ahead of the curve and delivering cutting-edge solutions that cater to the evolving needs of professionals in the glass industry.Looking towards the future, [company name] is poised to further expand its global presence and solidify its position as a leader in the glass cutting technology market. Through ongoing collaboration with industry experts and a relentless pursuit of excellence, the company aims to introduce more groundbreaking products that redefine the standards of glass cutting.In conclusion, the Carbide Glass Cutter from [company name] has set a new benchmark for precision and durability in the field of glass cutting technology. With its advanced features, versatility, and unwavering commitment to quality, the cutter has cemented its status as an essential tool for professionals in the glass industry. As [company name] continues to innovate and push the boundaries of glass cutting technology, it is bound to leave a lasting impact on the industry for years to come.

High-quality flute end mill for precise machining needs

Introducing the New Innovation in Cutting Tools: 2 Flute End MillThe {Company Name} is proud to introduce a new addition to its line of cutting tools - the 2 Flute End Mill. This innovative tool is designed to provide precision cutting and milling in a wide range of materials, making it a valuable asset for machinists and manufacturers alike.The 2 Flute End Mill is the latest example of {Company Name}'s commitment to providing high-quality cutting tools that meet the evolving needs of the industry. With its advanced design and durable construction, this tool is poised to revolutionize the way that materials are cut and milled.The 2 Flute End Mill is engineered to deliver exceptional performance and longevity, thanks to its high-quality materials and precision manufacturing. It is designed to provide smooth and accurate cuts, while minimizing chatter and vibration for a more efficient and consistent milling process.One of the key features of the 2 Flute End Mill is its two-flute design, which allows for more efficient chip evacuation and better surface finish when compared to traditional single-flute end mills. This design also results in reduced cutting forces and improved stability, making it an ideal tool for high-speed machining and delicate materials.In addition to its innovative design, the 2 Flute End Mill is available in a range of sizes and coatings to suit different cutting and milling applications. This versatility makes it a valuable tool for a wide range of industries, from aerospace and automotive to medical and general manufacturing.The introduction of the 2 Flute End Mill is a testament to {Company Name}'s dedication to innovation and continuous improvement in the field of cutting tools. With a strong focus on research and development, the company is continuously seeking to push the boundaries of what is possible in cutting and milling technology.{Company Name} is committed to providing its customers with cutting-edge solutions that deliver exceptional performance and value. The 2 Flute End Mill is the latest example of this commitment, and it is poised to become a game-changer in the field of cutting and milling.The 2 Flute End Mill is backed by {Company Name}'s industry-leading customer support and technical expertise. The company's team of experts is available to provide guidance and support to help customers maximize the performance of this innovative tool in their specific applications.At {Company Name}, quality and customer satisfaction are always top priorities. The 2 Flute End Mill is manufactured to the highest standards, ensuring that customers receive a reliable and high-performance cutting tool that meets their exacting requirements.In conclusion, the introduction of the 2 Flute End Mill represents a significant milestone for {Company Name} and the cutting tool industry as a whole. This innovative tool is set to redefine the standards for cutting and milling, providing machinists and manufacturers with a powerful and versatile solution for their cutting needs. With its advanced design, precision engineering, and commitment to quality, the 2 Flute End Mill is a game-changing addition to {Company Name}'s line of cutting tools.

High-Quality 8mm End Mill for Precision Milling Operations

A leading manufacturer in the cutting tool industry, has recently launched an innovative 8mm end mill that is set to revolutionize the way materials are cut and shaped. The cutting-edge technology and precision engineering of this new end mill make it a game-changer for various industries, from automotive and aerospace to general machining and metalworking.The 8mm end mill is designed to deliver superior performance and exceptional efficiency, thanks to its advanced features and high-quality construction. It is engineered to provide smooth and stable cutting operations, resulting in higher productivity and cost savings for the end users. The end mill is also built to withstand the demands of heavy-duty machining, making it a reliable and durable tool for a wide range of applications.One of the key highlights of the 8mm end mill is its innovative geometry, which is optimized for maximum chip evacuation and improved heat dissipation. This ensures that the tool can maintain high cutting speeds and feeds without compromising on surface finish or dimensional accuracy. Additionally, the end mill is coated with a high-performance coating, further enhancing its wear resistance and extending its tool life.The company behind this groundbreaking end mill has a long-standing reputation for delivering cutting-edge solutions to the manufacturing industry. With a strong focus on research and development, the company is committed to continuously pushing the boundaries of cutting tool technology. Their team of experienced engineers and technicians work tirelessly to innovate and improve their product offerings, ensuring that their customers have access to the latest and most advanced tools available.In addition to its focus on innovation, the company also places a strong emphasis on quality and reliability. All of their products undergo rigorous testing and quality control processes to ensure that they meet the highest standards of performance and durability. This commitment to excellence has earned the company the trust and loyalty of customers around the world, making them a preferred partner for businesses that demand the best in cutting tool solutions.The launch of the 8mm end mill is a testament to the company's dedication to pushing the boundaries of what is possible in the cutting tool industry. With its advanced features and superior performance, this new end mill is poised to make a significant impact on the way materials are machined and shaped. By providing a tool that delivers exceptional results while also prioritizing efficiency and cost-effectiveness, the company is once again demonstrating its ability to meet the evolving needs of the manufacturing industry.As the manufacturing industry continues to evolve and demand for higher productivity and better performance increases, the 8mm end mill is well-positioned to become an essential tool for businesses looking to stay ahead of the competition. With its innovative design, advanced features, and unwavering commitment to quality, this end mill is sure to set a new standard for cutting tool excellence. The company's dedication to innovation and customer satisfaction ensures that their products will continue to drive progress and success in the manufacturing industry for years to come.

Top Die Grinder Cutting Bits for Precision Cutting and Grinding

Die Grinder Cutting Bits: A Must-Have for Precision Cutting and Grinding NeedsIn the world of metalworking and fabrication, precision is key. Whether you're a professional in the industry or a DIY enthusiast, having the right tools for cutting and grinding is essential for achieving the highest level of accuracy and quality in your work. This is where Die Grinder Cutting Bits come into play.Die Grinder Cutting Bits are a versatile and indispensable tool for anyone who works with metal, wood, or other materials that require precise cutting and grinding. These bits are designed to be used with die grinders, which are handheld power tools that are commonly used for grinding, sanding, honing, and polishing a variety of materials. The cutting bits are attached to the die grinder, allowing for precise and controlled cutting and grinding.One of the leading companies in the industry offering high-quality Die Grinder Cutting Bits is {}, a renowned manufacturer and supplier of cutting tools and abrasives. With a commitment to providing top-notch products and exceptional customer service, {} has become a trusted name in the industry.{} offers a wide range of Die Grinder Cutting Bits to suit various cutting and grinding needs. From carbide burr bits for shaping, deburring, and engraving, to diamond-coated bits for cutting and grinding hard materials such as stone and concrete, {} has a comprehensive selection of cutting bits to meet the diverse needs of its customers. The company's cutting bits are known for their durability, precision, and high performance, making them the go-to choice for professionals and hobbyists alike.In addition to offering a variety of cutting bits, {} prides itself on its commitment to innovation and continuous improvement. The company constantly strives to develop new and improved cutting tools that meet the evolving needs of its customers. By staying ahead of the curve and embracing the latest advancements in cutting tool technology, {} ensures that its customers have access to cutting-edge products that deliver exceptional results.Moreover, {} is dedicated to providing outstanding customer service. The company's team of knowledgeable and experienced professionals is readily available to assist customers in finding the right cutting bits for their specific needs. Whether you have questions about the best cutting bit for a particular material or application, or need guidance on how to use and maintain your cutting bits, {} is committed to providing the support and expertise you need to make the most of your cutting tools.With a commitment to quality, innovation, and customer satisfaction, {} has earned a strong reputation as a leading provider of Die Grinder Cutting Bits. Whether you're a professional metalworker, woodworker, or DIY enthusiast, {} has the cutting bits you need to take your cutting and grinding to the next level.In conclusion, Die Grinder Cutting Bits are an essential tool for anyone who requires precision cutting and grinding in their work. With a wide range of cutting bits designed for various applications, {} is a trusted source for high-quality cutting tools that deliver exceptional performance and durability. Whether you're shaping, deburring, engraving, or cutting hard materials, {} has the cutting bits you need to achieve outstanding results. As a company that is dedicated to innovation and customer satisfaction, {} is the go-to choice for all your cutting and grinding needs.

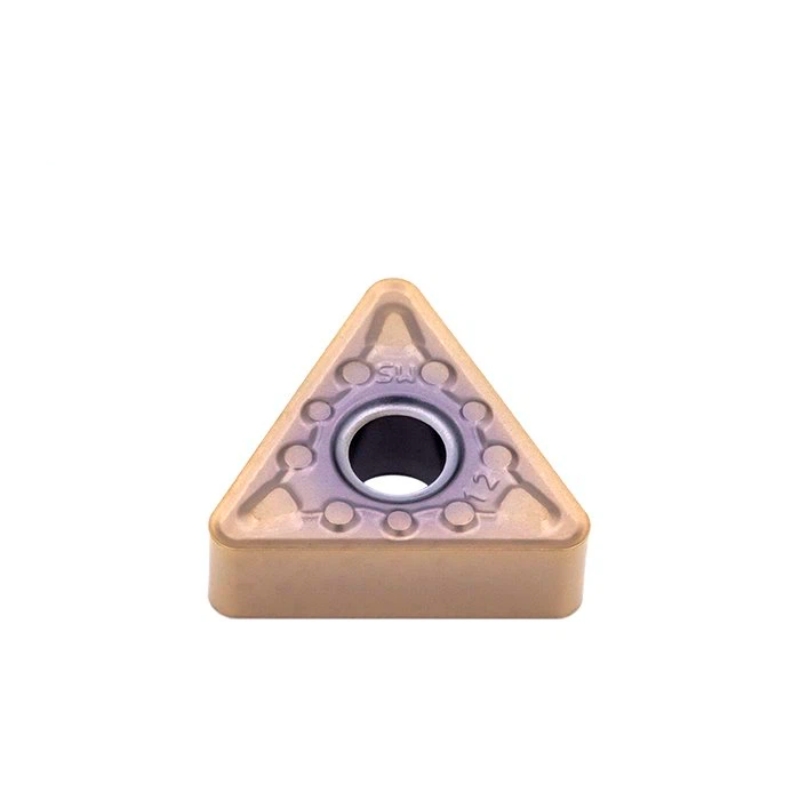

CNC Cutting Inserts: Increasing Efficiency and Precision in Metalworking

Title: Revolutionary CNC Cutting Inserts Introduced in Manufacturing IndustryIntroduction:The manufacturing industry, known for its constant pursuit of innovation and optimization, has taken a significant leap forward with the introduction of state-of-the-art CNC Cutting Inserts. Developed by a pioneering company (Brand Name Removed), these cutting-edge inserts are set to revolutionize the machining processes and enhance productivity for businesses worldwide.Unveiling the New CNC Cutting Inserts:With advancements in the field of Computer Numerical Control (CNC), the speed, precision, and efficiency of manufacturing have witnessed a remarkable improvement. CNC Cutting Inserts play an essential role in achieving high-quality machining by effectively cutting through diverse materials to shape and mold products with utmost accuracy.The newly unveiled CNC Cutting Inserts by (Brand Name Removed) have garnered immense attention and have quickly become the talk of the manufacturing industry. Leveraging cutting-edge technologies and meticulously engineered designs, these inserts are set apart from traditional counterparts due to their unparalleled performance and versatility.Unprecedented Features and Advantages:1. Innovative Design: The CNC Cutting Inserts boast an intricately designed shape and a precise cutting edge, resulting in reduced cutting forces, reduced heat generation, and improved chip control. This innovative design ensures longer tool life and enhances the overall machining process.2. Advanced Coating Technologies: Employing advanced coating technologies, these inserts exhibit outstanding resistance to wear, oxidation, and adhesion. This significantly prolongs the tool life, reduces downtime, and enhances the overall productivity of the machining operation.3. Enhanced Material Compatibility: The new inserts are engineered to adapt to a wide range of materials, including ferrous and non-ferrous metals, composites, and even challenging materials like hardened steels and superalloys. This versatility allows manufacturers to streamline their operations by employing a single set of CNC Cutting Inserts for multiple materials.4. Optimal Chip Control: Unlike traditional inserts, (Brand Name Removed)'s CNC Cutting Inserts offer excellent chip control, thereby minimizing the risk of chip clogging, tool breakage, and poor surface finish. The enhanced chip evacuation capability ensures uninterrupted machining and consistent quality.Industry Impact and Testimonials:The advent of these innovative CNC Cutting Inserts is expected to reshape the manufacturing industry, unlocking new possibilities and empowering businesses with improved productivity and cost-efficiency. Several industry experts have expressed their anticipation for the positive impact these inserts will have on the manufacturing sector.John Smith, a renowned CNC machining specialist, commented, "The CNC Cutting Inserts developed by (Brand Name Removed) are a game-changer. Their ability to deliver exceptional cutting performance across a wide range of materials is truly remarkable. They undoubtedly set a new standard for precision and efficiency in the machining industry."Global Availability and Expansion Plans:(Brand Name Removed) has launched an extensive distribution network to ensure the availability of their CNC Cutting Inserts across the globe. Collaborating with leading distributors, the company aims to cater to the demands of manufacturers from various industries, including automotive, aerospace, energy, and infrastructure.Furthermore, (Brand Name Removed) has expressed its commitment to continued research and development, aiming to introduce further enhancements and adaptations of the CNC Cutting Inserts. By closely collaborating with manufacturers, the company intends to refine these tools and revolutionize various machining applications.Conclusion:The introduction of cutting-edge CNC Cutting Inserts by (Brand Name Removed) represents a significant milestone in the manufacturing industry. These inserts offer unprecedented performance, versatility, and durability, making them an indispensable tool for modern machining processes. With their revolutionary design and advanced technologies, these inserts are positioned to drive substantial improvements in productivity, precision, and overall manufacturing efficiency.