| Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

| CVD | PVD | ||||||||||||||

| VK4215 | VK4315 | VK4225 | VK4325 | VK4235 | VK4335 | VK1025 | VK1325 | VK1525 | VK1328 | VR1010 | VR1325 | ||||

| P Semi Finishing | SNMG120404-AM | 1.00- 5.00 | 0.12- 0.40 | • | O | • | O | O | |||||||

| SNMG120408-AM | 1.20- 5.00 | 0.15- 0.55 | • | O | • | O | O | ||||||||

| SNMG120412-AM | 1.50- 5.00 | 0.20- 0.55 | • | O | • | O | O | ||||||||

| SNMG150612-AM | 2.00- 7.00 | 0.30- 0.65 | • | O | • | O | O | ||||||||

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

| CVD | PVD | ||||||||||||||

| VK4215 | VK4315 | VK4225 | VK4325 | VK4235 | VK4335 | VK1025 | VK1325 | VK1525 | VK1328 | VR1010 | VR1325 | ||||

| P Rough Machining | SNMG120408-AR | 2.50- 6.00 | 0.25- 0.70 | • | O | ||||||||||

| SNMG120412-AR | 2.50- 6.00 | 0.30- 0.70 | • | O | |||||||||||

| SNMG120416-AR | 2.50- 6.00 | 0.40- 0.70 | • | O | |||||||||||

| SNMG150612-AR | 2.15- 6.40 | 0.25- 0.50 | • | O | |||||||||||

| SNMG190612-AR | 2.15- 6.40 | 0.25- 0.50 | • | O | |||||||||||

| SNMG190616-AR | 2.85- 7.60 | 0.30- 0.65 | • | O | |||||||||||

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

| CVD | PVD | ||||||||||||||

| VK4215 | VK4315 | VK4225 | VK4325 | VK1025 | VK1325 | VK1525 | VK1328 | VR1010 | VR1325 | VR1525 | VR1330 | ||||

| M Finishing | SNMG120404-BF | 0.25- 3.20 | 0.05- 0.15 | • | • | O | O | ||||||||

| SNMG120408-BF | 0.50- 3.20 | 0.10- 0.30 | • | • | O | O | |||||||||

| SNMG120412-BF | 0.75- 3.20 | 0.15- 0.45 | • | • | O | O | |||||||||

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

| CVD | PVD | ||||||||||||||

| VK4215 | VK4315 | VK4225 | VK4325 | VK1025 | VK1325 | VK1525 | VK1328 | VR1010 | VR1325 | VR1525 | VR1330 | ||||

| M Semi Finishing | SNMG120404-BM | 0.30- 4.20 | 0.08- 0.25 | O | O | • | O | O | |||||||

| SNMG120408-BM | 0.65- 4.20 | 0.15- 0.45 | O | O | • | O | O | ||||||||

| SNMG120412-BM | 0.95- 4.20 | 0.25- 0.65 | O | O | • | O | O | ||||||||

| SNMG150608-BM | 0.65- 5.20 | 0.15- 0.45 | O | O | • | O | O | ||||||||

| SNMG150612-BM | 0.95- 5.20 | 0.25- 0.65 | O | O | • | O | O | ||||||||

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

| CVD | PVD | ||||||||||||||

| VK4215 | VK4315 | VK4225 | VK4325 | VK1025 | VK1325 | VK1525 | VK1328 | VR1010 | VR1325 | VR1525 | VR1330 | ||||

| M Rough Machining | SNMG120404- BR | 0.30-4.20 | 0.08- 0.25 | O | O | O | • | • | O | ||||||

| SNMG120408- BR | 0.65- 4.20 | 0.15- 0.45 | O | O | O | • | • | O | |||||||

| SNMG120412- BR | 0.95- 4.20 | 0.25- 0.66 | O | O | O | • | • | O | |||||||

| SNMG150608- BR | 0.65- 5.20 | 0.15- 0.44 | O | O | O | • | • | O | |||||||

| SNMG150612- BR | 0.95- 5.20 | 0.25- 0.66 | O | O | O | • | • | O | |||||||

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||

| CVD | |||||||

| VK3020 | VK3040 | VK3315 | VK3415 | ||||

| K Semi Finishing | SNMG120404-CM | 0.40-4.20 | 0.08-0.25 | • | O | ||

| SNMG120408-CM | 0.80-4.20 | 0.15-0.45 | • | O | |||

| SNMG120412-CM | 1.20-4.20 | 0.25-0.65 | • | O | |||

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade | ||||||||||||

| CVD | PVD | |||||||||||||||

| VK4215 | VK4315 | VK4225 | VK4325 | VK1025 | VK1325 | VK1525 | VK1328 | VR1010 | VR1520 | VR1525 | VR1028 | VR1330 | ||||

| S Semi Finishing | SNMG120404-DM | 0.40- 3.90 | 0.08- 0.25 | O | O | O | • | • | O | O | ||||||

| SNMG120408-DM | 0.80- 3.90 | 0.15- 0.45 | O | O | O | • | • | O | O | |||||||

| SNMG120412-DM | 1.20- 3.90 | 0.25- 0.65 | O | O | O | • | • | O | O | |||||||

| SNMG120416-DM | 1.80- 3.90 | 0.30- 0.90 | O | O | O | • | • | O | O | |||||||

| SNMG150608-DM | 0.80- 3.90 | 0.15- 0.45 | O | O | O | • | • | O | O | |||||||

| SNMG150612-DM | 1.20- 3.90 | 0.25- 0.65 | O | O | O | • | • | O | O | |||||||

| SNMG150616-DM | 1.80- 3.90 | 0.30- 0.90 | O | O | O | • | • | O | O | |||||||

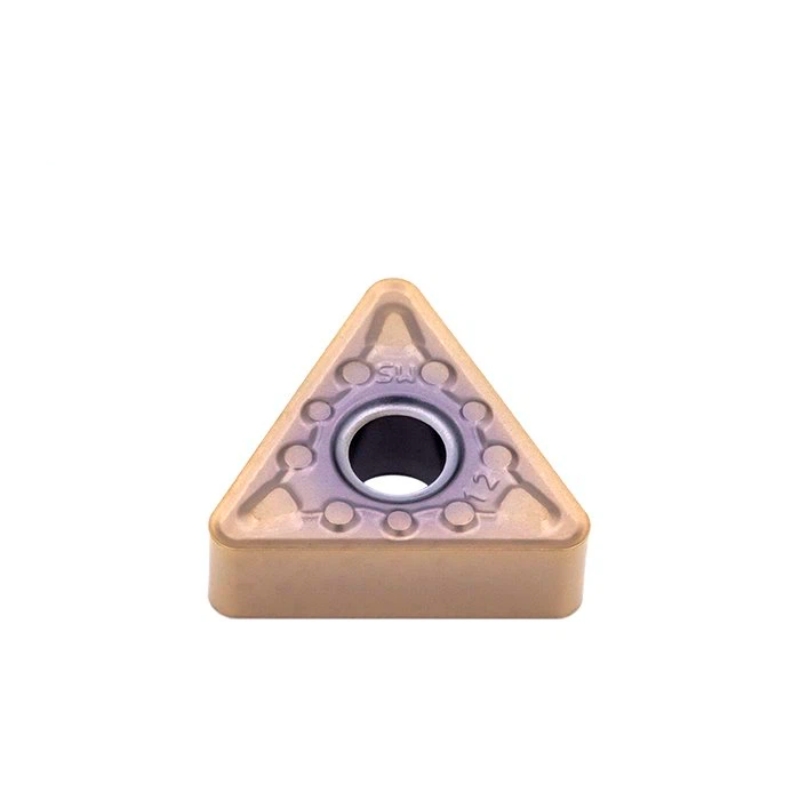

| Length | Size(mm) | |||

| IC | S | d | r | |

| 12 | 12.7 | 4.76 | 5.16 | 0.4-1.2 |

| 15 | 15.875 | 6.35 | 6.35 | 0.8-1.2 |

1.What is a thread insert called? A threaded insert that is inserted into an object to add a threaded hole. 2.What are thread inserts used for? A threaded insert is a sleeve with a threaded interior that can accept a bolt or threaded fastener. The insert can have different dimensions, be made of different materials, and come in different configurations or tooling; its design will hold fast in thin or soft materials, making the threaded fastener secure. 3.What is the Warranty for the products? We use 100% virgin material to guarantee products high performance, We own high precision grading machine to control geometry dimensions and guarantee the lifetime of our products, which can satisfy every working condition. 4.Is non-standard products available? Yes, we accept OEM ODM orders 5.Do you offer samples? Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy. Application for turning and milling carbon and alloy steels, tools steel and stainless steel.

1.What is a thread insert called? A threaded insert that is inserted into an object to add a threaded hole. 2.What are thread inserts used for? A threaded insert is a sleeve with a threaded interior that can accept a bolt or threaded fastener. The insert can have different dimensions, be made of different materials, and come in different configurations or tooling; its design will hold fast in thin or soft materials, making the threaded fastener secure. 3.What is the Warranty for the products? We use 100% virgin material to guarantee products high performance, We own high precision grading machine to control geometry dimensions and guarantee the lifetime of our products, which can satisfy every working condition. 4.Is non-standard products available? Yes, we accept OEM ODM orders 5.Do you offer samples? Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy. Application for turning and milling carbon and alloy steels, tools steel and stainless steel.